What is 3D Printing?

Additive manufacturing is a process in which a digital file is used to produce real, solid three-dimensional objects. That technique is carried out by progressively laying down very thin layers of material, and could be considered to be the opposite of traditional manufacturing which is a subtractive process relying on removal of material by cutting, grinding, or machining. In a sense, many 3D printers are a product of a technological and physical marriage between a hot glue gun and a traditional text printer.

Why It Matters

Also known as 'rapid manufacturing', 3D printing has been too expensive for home use, until now. A flood of established, as well as start-up manufacturers, are almost tripping over each other to bring new machines to the consumer market. Those machines typically produce objects from a variety of plastics, but some very expensive machines, made primarily for industry, can produce products from several substances, including metal, glass, and ceramic, and even food materials.

Getting Real at Home

New models of 3D printers are being released so rapidly that it is probably one of the fastest changing technologies moving into consumer-level use, at prices now becoming affordable for hobbyists, technophiles and artists. If an object can be conceived in the mind and translated into a CAD (Computer Aided Design) file, it can probably be manufactured in the home environment, if it meets the size and materials limitations of the machine being used.

Partial List of 3D Printers

3D Systems is the company that makes the consumer-level BotMill, RapMan, and 3dTouch, and also the ProJet series for professional and industrial use. The RapMan is delivered in kit form. The ProJet 3500 is capable of making cast-friendly wax for rapid-foundry production, and also specialized materials for digital production of medical implants, dental models and prosthesis, and one-of-a-kind items such as jewelry.

Cubify is a consumer initiative service platform of 3D Systems, and is releasing one of the most consumer-friendly machines on the market, known as the Cube. That machine, however, will lock users into proprietary materials cartridges. Cubify also charges customers for downloading designs. Other manufactures, such as MakerBot, provide that service at no additional charge.

B9Creator has an anodized aluminum body and stainless-steel hardware, and uses a technology not typical of other machines, allowing for creation of fragile, detailed, and complex objects, with very high definition. The B9Creator employs a 1,024 x 768 pixel digital light processing (DLP) projector to beam an image onto a layer of liquid, photo-initiated polymer resin, creating layers as thin as 50 to 100 microns. Fifty microns is equivalent to about two-thousandths of an inch. In the vertical axis the B9 has a resolution finer than 10 microns via software options.

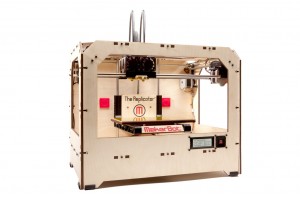

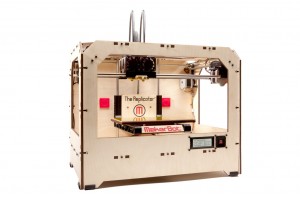

MakerBot is producing the company's first prepackaged product, the MakerBot Replicator, but a few assembly steps are required. It may be the most full-featured consumer-grade 3D printer even though the body is made from laser-cut plywood. The MakerBot Replicator has a five-button control pad, a four-line LED screen, and a built-in SD card slot, which are features not usually found on consumer-level 3D printers. That unit can be ordered with single or dual-extruder print heads. With its large build area of 8.9 x 5.7 x 5.9 inches, the Replicator facilitates creation of the largest objects of any current consumer-grade 3D printer. Installing and using the software is a complex challenge, and seems to indicate this product is best used by technophiles and engineers.

Solidoodle may be the little engine that could. That small Brooklyn, New York based company is releasing the Solidoodle 2, a pre-assembled unit starting at US-$500. That unit does not include a heated build platform at that price, but the Pro model does for an added cost of $50. Prices for all manufacturers are dropping so quickly that price mentions are avoided for most of this article. However, the entry-level price for the pre-assembled Solidoodle 2 is noteworthy. Sam Cervantes, CEO and founder of Solidoodle previously worked as an aerospace engineer, and also served as the Chief Operations Officer of a New York based 3D printing company.

Assessment

At least for the next two years this technology is probably best for die-hard do-it-yourself technophiles, hobbyists, engineers, artists, and those who absolutely must be on the bleeding edge of new technology. Be prepared to bleed money and a substantial investment in your time and patience.

Laptop & Tablet Parts

Laptop & Tablet Parts