Slice One - The Butler Did Not Do It

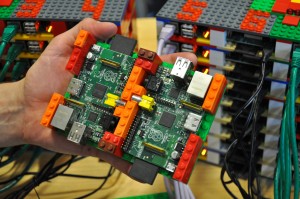

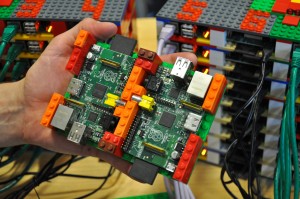

A team of computational engineers at the United Kingdom's University of Southampton pulled off this caper, and published a do-it-yourself manual to guide others in similar shenanigans.

The design was developed by Professor Simon Cox who said in a prepared statement: "As soon as we were able to source sufficient Raspberry Pi computers we wanted to see if it was possible to link them together into a supercomputer. We installed and built all of the necessary software on the Pi starting from a standard Debian Wheezy system image and we have published a guide so you can build your own supercomputer."

The machine's moniker is "Iridis-Pi", a derivative name from the university's Iridis supercomputer. Costing less than £2,500 (US-$4,060, excluding switches) the system has one terabyte (TB) of memory in the form of 16 gigabyte (GB) SD cards for each of the 64 Raspberry Pi computers. The system uses the free plug-in "Python Tools for Visual Studio" to develop code for the Pi boards, and uses MPI (Message Passing Interface) for communications between nodes via Ethernet. Power comes from a single 13-amp socket.

Slice Two - Board Revision 2.0 PCB

The non-profit Raspberry Pi Foundation has solicited feedback and the result is the announcement that a revised design known as revision 2.0 PCB will be produced.

The changes are numerous, but most are minor. In the words of the foundation itself: "We don’t believe that the changes are large enough to make it worth “holding on” for revision 2.0, unless you have a specific requirement to add an audio codec or you need mounting holes for some industrial application."

Slice Three - Raspberry Pi Now Made in the United Kingdom

Demand for Pi units has far exceeded expectations. The resulting volume now makes it possible to cost-effectively manufacture in the UK. Here is the summary directly from RaspberryPi.org. "Sony’s quality control system is legendary, their ability to manufacture fast and cleanly is superb, and they’ve already invested in adding PoP (Package on Package – the fiddly stuff where the Broadcom chip at the heart of the Raspberry Pi is stacked beneath the RAM chip) hardware manufacture ability and expansion capability just for us. They’re also able to take on the huge task (currently undertaken by RS and Farnell) of ensuring the parts used are sourced ethically and to the highest ecological standards – every component has to pass standard compliance via Sony’s Green Management programme."

The update continues: "The upshot of all this? Element14/Premier Farnell have made the decision to move the bulk of their Raspberry Pi manufacture to South Wales. Moving manufacture like this is an enormous undertaking; from the start of the process, it’s taken us (especially Pete), Farnell and Sony nearly six months to get all our respective ducks in a row. The initial contract will see the Pencoed plant producing 30,000 Raspberry Pis a month, and creating around 30 new jobs."

Laptop & Tablet Parts

Laptop & Tablet Parts